If You Think You Understand , Then Read This

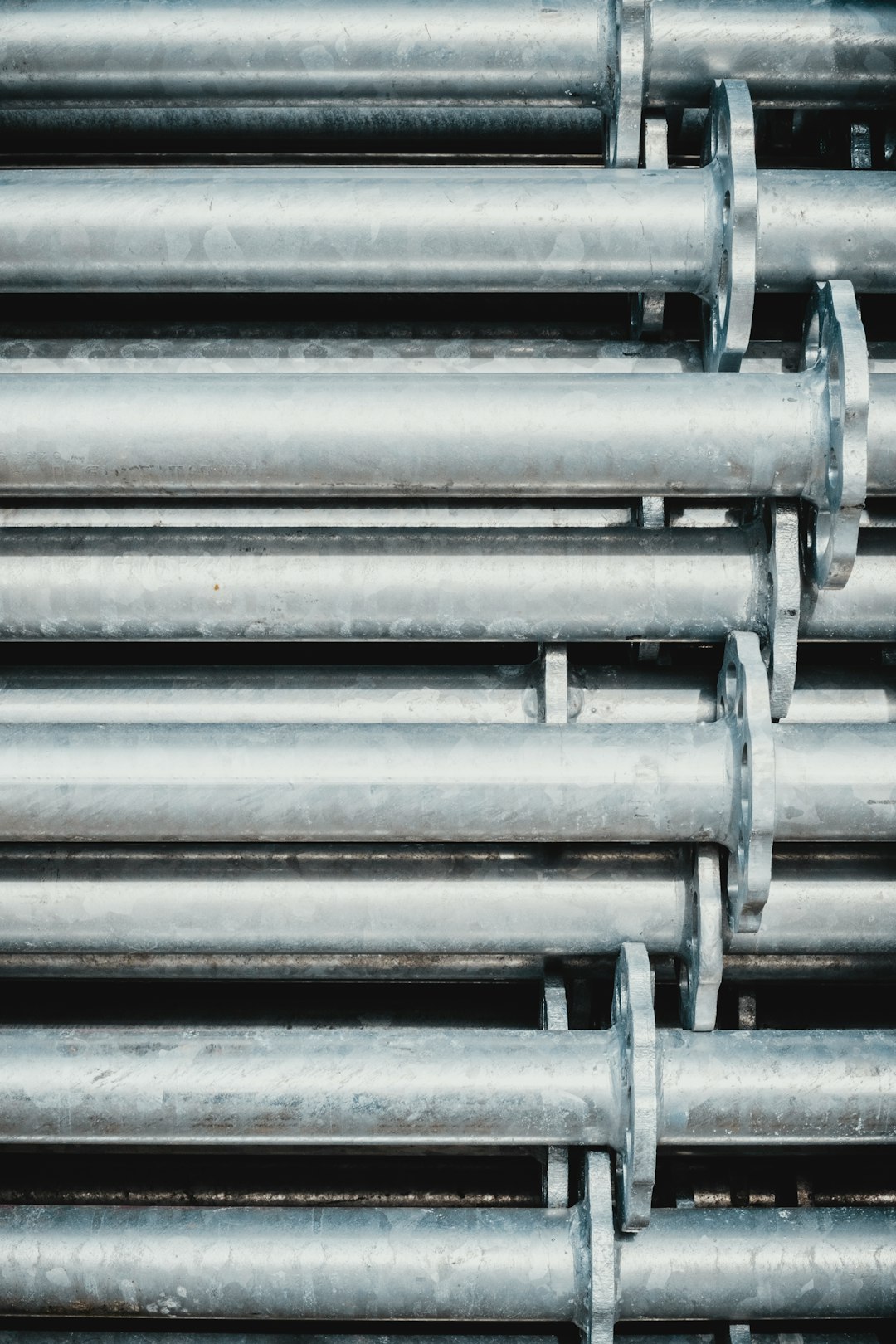

If you enjoy working on DIY projects or have a small business in the manufacturing industry, you understand the importance of finding versatile and cost-effective materials. When it comes to creating custom pieces and structures, small aluminum extrusion is an excellent choice. This article will explore the various benefits and applications of small aluminum extrusion, providing you with valuable insights to enhance your projects.

0 Picture Gallery: If You Think You Understand , Then Read This

Understanding Aluminum Extrusion

Before delving into the specifics of small aluminum extrusion, let’s first understand what the term means. Aluminum extrusion is a manufacturing process that involves forcing heated aluminum billets through a shaped die to form specific cross-sectional profiles. This process results in the creation of long and uniform pieces, known as aluminum extrusions.

Benefits of Small Aluminum Extrusion

When it comes to small-scale projects, small aluminum extrusion offers numerous advantages that make it a popular choice among DIY enthusiasts and small business owners. Here are some of the key benefits:

1. Versatility: Small aluminum extrusion allows you to create complex shapes and designs, giving you the freedom to bring your ideas to life. Whether you need customized brackets, frames, or trim pieces, aluminum extrusions can be easily tailored to meet your unique requirements.

2. Lightweight yet Durable: Despite its lightweight nature, aluminum extrusion is remarkably strong and sturdy. This combination of properties makes it an ideal material for various applications, such as building small structures, enclosures, or even decorative items.

3. Cost-effective: Small aluminum extrusions are cost-effective, particularly when compared to other materials like steel or copper. They not only save you money on initial material costs but also offer long-term savings due to their durability and low maintenance requirements.

Applications of Small Aluminum Extrusion

The versatility of small aluminum extrusion makes it suitable for a wide range of applications. Here are some common uses:

1. Furniture and Decorations: Aluminum extrusions can be used to create unique furniture pieces, such as tables, chairs, and shelving units. Their lightweight nature makes them easy to maneuver, while their durability ensures long-lasting performance.

2. Electronics and Electrical Components: From heat sinks and heatsinks to enclosures and brackets, small aluminum extrusions are a popular choice for manufacturing electronic and electrical components. The excellent thermal conductivity of aluminum helps dissipate heat efficiently, ensuring the longevity of electronic devices.

3. Automotive Accessories: Many automotive accessories, such as trim pieces, roof racks, and grille guards, are made using small aluminum extrusion. The material’s lightweight and corrosion-resistant properties make it an excellent choice for enhancing the functionality and aesthetics of vehicles.

4. Signage and Displays: Small aluminum extrusions are widely used in the signage and display industry. Whether it’s creating retail store fixtures, outdoor signs, or exhibition displays, aluminum extrusions offer the necessary strength and flexibility to meet various design requirements.

Tips for Working with Small Aluminum Extrusion

To ensure successful projects using small aluminum extrusion, keep the following tips in mind:

1. Accurate Measurements: Take precise measurements before ordering or cutting aluminum extrusions. This will help you avoid wastage and ensure that the final product fits your intended application perfectly.

2. Proper Joining Techniques: Familiarize yourself with various joining techniques suitable for aluminum extrusions, such as welding, bolting, or adhesive bonding. Choosing the right method will ensure the strength and stability of your project.

3. Surface Finishing: Consider the desired surface finish of your aluminum extrusion. Whether you prefer a painted, anodized, or powder-coated surface, make sure to choose the appropriate finish to enhance the appearance and protect the material from corrosion.

In conclusion, small aluminum extrusion is an incredibly versatile and cost-effective solution for small-scale projects. Its lightweight yet durable nature, along with the ability to create complex shapes, makes it a popular choice among DIY enthusiasts and small business owners. By understanding its benefits and applications, and following proper techniques, you can unleash your creativity and achieve outstanding results in your projects. So, why wait? Start exploring the possibilities of small aluminum extrusion today and bring your vision to life!

5 Takeaways That I Learned About

Why Aren’t As Bad As You Think

This post topic: Advertising & Marketing